»Load-cells

We manufacture both standard and customer sensors

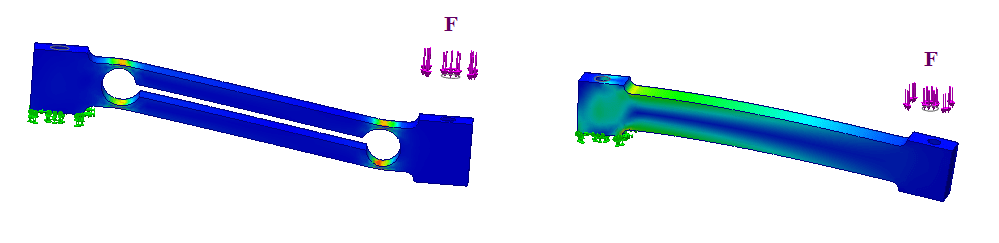

Do you need sensitive meters and sensors for pressure, traction, force, weight, acceleration or torque that are resistant to the environment and measure values in the necessary range and with accuracy? We will design and manufacture sensors according to the customer’s specifications to meet all the required parameters. Strain gauges are an integral part of structural testing in aviation, the automotive industry, as well as in healthcare and research laboratories.

Sensors with strain gauges

They have a high output signal – tens to low hundreds of mV, usability even in an environment with disturbing electromagnetic influences, minimal demands on the capacity of power supplies, long life – up to 109 cycles of full working load, resistance to continuous overloading up to 200% of the nominal range, high reliability.

Sensors can be powered by direct current or alternating current. The size of the output signal of the sensors is proportional to the size of the supply current, which is chosen in proportion to the intensity of resistance heat removal from the strain gauge. The supply current is therefore proportional to the weight of the measuring parts of the strain gauge and ranges from 1 mA to 30 mA. The long-term stability of sensors with silicon strain gauges is, as with all strain gauge sensors, within the limits of 0.015% to 0.05% per year. The hysteresis of the sensors at nominal load usually does not exceed 0.05% of the nominal signal. The price of the sensor depends on its arrangement and the difficulty of production.

Sensors with metal foil strain gauges

We also manufacture strain gauges equipped with foil metal strain gauges. We buy these strain gauges from global manufacturers.

Compared to sensors with solid state strain gauges, they have:

- lower output signal (sensitivity up to 4 mV/V)

- lower temperature coefficient of deformation sensitivity

- smaller combined error (hysteresis + non-linearity)

- less safe overload capacity

- temperature self-compensation

Entering the sensor

We design and modify sensors according to customer requirements. When designing the sensor, it is necessary to specify the required parameters:

- measuring range

- required accuracy

- working temperature range

- aggressiveness of the work environment

- maximum and minimum dimensions

- method of attachment, possibly the shape and dimensions of the contact surfaces

- cable type and length

- requirements for electronics (power supply, output signal, design, functions, …)